Controlled atmosphere storage emerges as a highly successful innovation in the fruit and vegetable sector of the 20th century. This technology focuses on adjusting oxygen (O2) levels and elevating carbon dioxide (CO2) compared to the ambient air. It may also include the removal of ethylene and the introduction of carbon monoxide. The core of controlled atmosphere storage involves continuous monitoring and precise adjustment of these gases within the storage container to meet predetermined levels.

Excessive levels of CO2 or insufficient O2 can lead to irreversible damage to fruits or vegetables, with the manifestations of damage varying across products and depending on the intensity of the impact.

The primary use of controlled atmosphere storage has been in slowing down the ripening process of apples and pears. The widespread adoption of mechanized handling, utilizing bulk bins and pallets, coupled with advancements in technology for maintaining precise conditions of temperature, humidity, oxygen, carbon dioxide, and ethylene, has resulted in a significant global expansion of controlled atmosphere storage since the mid-20th century.

Another application of controlled atmosphere storage is evident in grain storage. Fundamental techniques involve drying the grain to below 12% moisture content before sealing it in a structure or silo. Drying is achieved using aeration fans as the grain enters a controlled atmosphere enclosure. Throughout the storage period, aeration and fans are deployed to control temperature and humidity.

Controlled Atmosphere Storage Technology

The primary goal of food is to promote our health and general well-being. Food science entails comprehending the characteristics, composition, and behaviors of food constituents in different situations, such as storage, handling, and consumption.

Showing posts with label technology. Show all posts

Showing posts with label technology. Show all posts

December 24, 2023

March 9, 2023

Membrane Distillation

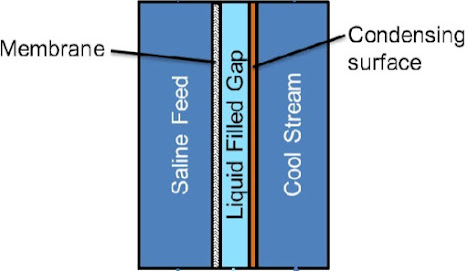

Membrane Distillation is a promising technology for treating saline water and wastewater with high rejection factors, which cannot be accomplished by conventional technologies.

Membrane Distillation uses low-grade thermal energy to drive desalination, to remove non-volatile contaminants or to recover other components. In the Membrane Distillation process, only vapor molecules are allowed to pass through the hydrophobic membrane pores. The pressure difference resulting from the temperature difference is applied between the surfaces of the hydrophobic membrane, so the separation takes place.

Compared with other conventional separation technologies such as reverse osmosis, nanofiltration, or thermal distillation, Membrane Distillation is very attractive due to mild operating conditions such as low temperature and atmospheric pressure, and 100% theoretical salt rejection.

Other key advantages of membrane distillation processes over conventional separation technologies are:

*Relatively lower energy costs as compared to distillation, reverse osmosis, and pervaporation;

*A considerable rejection of dissolved, non-volatile species;

*Much lower membrane fouling as compared with microfiltration, ultrafiltration, and reverse osmosis; reduced vapor space as compared to conventional distillation

Membrane Distillation has gained wide attention in the last decade for various separation applications, including the separation of salts, toxic heavy metals, oil, and organic compounds from aqueous solutions.

The most used membranes for Membrane Distillation are polypropylene (PP), polytetrafluoroethylene (PTFE), and polyvinylidene fluoride (PVDF). Among these, PTFE has advantages such as high chemical stability, high crystallinity, low intermolecular attraction, low surface energy, and high hydrophobicity.

Membrane Distillation

Membrane Distillation uses low-grade thermal energy to drive desalination, to remove non-volatile contaminants or to recover other components. In the Membrane Distillation process, only vapor molecules are allowed to pass through the hydrophobic membrane pores. The pressure difference resulting from the temperature difference is applied between the surfaces of the hydrophobic membrane, so the separation takes place.

Compared with other conventional separation technologies such as reverse osmosis, nanofiltration, or thermal distillation, Membrane Distillation is very attractive due to mild operating conditions such as low temperature and atmospheric pressure, and 100% theoretical salt rejection.

Other key advantages of membrane distillation processes over conventional separation technologies are:

*Relatively lower energy costs as compared to distillation, reverse osmosis, and pervaporation;

*A considerable rejection of dissolved, non-volatile species;

*Much lower membrane fouling as compared with microfiltration, ultrafiltration, and reverse osmosis; reduced vapor space as compared to conventional distillation

Membrane Distillation has gained wide attention in the last decade for various separation applications, including the separation of salts, toxic heavy metals, oil, and organic compounds from aqueous solutions.

The most used membranes for Membrane Distillation are polypropylene (PP), polytetrafluoroethylene (PTFE), and polyvinylidene fluoride (PVDF). Among these, PTFE has advantages such as high chemical stability, high crystallinity, low intermolecular attraction, low surface energy, and high hydrophobicity.

Membrane Distillation

April 30, 2016

Definition of biotechnology

Biotechnology has been broadly defined as the utilization of biologically derived molecules, structures, cells or organisms to carry out a specific process. This is true of many established food processes – for example, cheesemaking and brewing.

The beauty of modern biotechnology lies in the specificity. The biotechnologist can target only one or two protein molecules for change in an organism containing thousands of proteins.

The seemingly minor alterations can have profound effects. The amount of an important flavor, color or enzyme may be increased many fold. It can allow crops to grow under marginal to poor conditions.

With a few exceptions, most short-term results of modern biotechnical applied to food production will be invisible to the consumer’s eye.

However, indirect effects on existing product, such as cost savings and product improvements, will be far reaching. It is therefore important for the public to be informed of the benefits that the biotechnological revolution can provide.

Definition of biotechnology

The beauty of modern biotechnology lies in the specificity. The biotechnologist can target only one or two protein molecules for change in an organism containing thousands of proteins.

The seemingly minor alterations can have profound effects. The amount of an important flavor, color or enzyme may be increased many fold. It can allow crops to grow under marginal to poor conditions.

With a few exceptions, most short-term results of modern biotechnical applied to food production will be invisible to the consumer’s eye.

However, indirect effects on existing product, such as cost savings and product improvements, will be far reaching. It is therefore important for the public to be informed of the benefits that the biotechnological revolution can provide.

Definition of biotechnology

February 11, 2014

New technology in food industry

Technological advance gathered speed in all areas of food technology as the 20th century progressed.

‘Instant’ coffee was invented in 1901, the first patent for hydrogenating fats and oils was issued in 1903, flavor enhancer, monosodium glutamate was isolated from seaweed in 1908.

New and alternative food processing methods, as well as novel combinations of existing methods, are continually being sought by industry in pursuit of producing better quality foods economically.

Hence, new innovations, technologies and concepts continue to emerge. The developments in recombinant DNA technology offer the opportunity not only of better controlling existing food processes, but also of developing entirely new approach to quality control and food product development.

The potential of this technology to benefit the food processing industry and to improve food quality such as appearance, texture, flavor, shelf-life ease of processing and nutritive value is enormous and its true economic impact .

Food processing has become more sophisticated and diverse in response to the growing demand for quality foods.

Strategies to meet such demands include modification to existing food processing techniques and the adoption of novel processing technologies.

New technology may reduce the number of existing jobs, but many studies show that it creates new demand, either by increasing productivity and hence real incomes, or by creating new goods.

Economists have generally argued that in the long run new technology creates more jobs that it eliminates. Today the world of food technology has a handful of options to explore that could make the food industry more diverse, competitive and efficient.

New technology in food industry

‘Instant’ coffee was invented in 1901, the first patent for hydrogenating fats and oils was issued in 1903, flavor enhancer, monosodium glutamate was isolated from seaweed in 1908.

New and alternative food processing methods, as well as novel combinations of existing methods, are continually being sought by industry in pursuit of producing better quality foods economically.

Hence, new innovations, technologies and concepts continue to emerge. The developments in recombinant DNA technology offer the opportunity not only of better controlling existing food processes, but also of developing entirely new approach to quality control and food product development.

The potential of this technology to benefit the food processing industry and to improve food quality such as appearance, texture, flavor, shelf-life ease of processing and nutritive value is enormous and its true economic impact .

Food processing has become more sophisticated and diverse in response to the growing demand for quality foods.

Strategies to meet such demands include modification to existing food processing techniques and the adoption of novel processing technologies.

New technology may reduce the number of existing jobs, but many studies show that it creates new demand, either by increasing productivity and hence real incomes, or by creating new goods.

Economists have generally argued that in the long run new technology creates more jobs that it eliminates. Today the world of food technology has a handful of options to explore that could make the food industry more diverse, competitive and efficient.

New technology in food industry

May 16, 2012

Fermentation

Fermentation technology is one of the oldest technologies employed in the food processing industry.

The term fermentation is derived from the Latin verb ‘fervere’, to boil, which describes the appearance of the action of yeast on extracts of fruits or malted grain during the production of alcoholic beverages.

In general it can be defined as the process of growing a culture of microorganisms in a nutrient medium at maintained physic-chemical conditions and thereby converting feed into desired end product.

Fermentation involves the breaking down of complex organic substance into smaller ones.

The microbial or animal cell obtains energy through glycolysis, splitting a sugar molecule and removing electrons from the molecules.

Fermented products encompass, but are not limited to wine, beer, vinegar, bread, soy sauce, sauerkraut, kimchi, pickled, olive, different fermented milk products, a large number of cheeses and a variety of sausages.

Many species of microorganisms are used for carrying out the process of fermentation to produce useful products. They include bacteria, fungi, algae and actinomycetes.

Several advantage of fermentation technology included:

*Produces value added and add variety to the human being’s diets.

*Preservation of the food.

*Food quality improvement through flavor development, nutrient enrichments.

*The food more nutritious.

*Detoxifies of foods

Today large numbers of chemicals are produced by fermentation technology with the advent genetic engineering and the developments in computer technology.

Fermentation

The term fermentation is derived from the Latin verb ‘fervere’, to boil, which describes the appearance of the action of yeast on extracts of fruits or malted grain during the production of alcoholic beverages.

In general it can be defined as the process of growing a culture of microorganisms in a nutrient medium at maintained physic-chemical conditions and thereby converting feed into desired end product.

Fermentation involves the breaking down of complex organic substance into smaller ones.

The microbial or animal cell obtains energy through glycolysis, splitting a sugar molecule and removing electrons from the molecules.

Fermented products encompass, but are not limited to wine, beer, vinegar, bread, soy sauce, sauerkraut, kimchi, pickled, olive, different fermented milk products, a large number of cheeses and a variety of sausages.

Many species of microorganisms are used for carrying out the process of fermentation to produce useful products. They include bacteria, fungi, algae and actinomycetes.

Several advantage of fermentation technology included:

*Produces value added and add variety to the human being’s diets.

*Preservation of the food.

*Food quality improvement through flavor development, nutrient enrichments.

*The food more nutritious.

*Detoxifies of foods

Today large numbers of chemicals are produced by fermentation technology with the advent genetic engineering and the developments in computer technology.

Fermentation

March 28, 2012

Bread baking principle

The function of baking is to present cereal flours in an attractive, palatable and digestible form.

Most bakery products are made of the same few ingredients – flour, shortening, sugar, eggs, water or milk and leavenings.

The dough is kneaded by hand or machine. After the dough rests for some time (about 2 hours) it is manipulated to push out the gas that has been evolved.

Three process are commence when the ingredients for bread making are mixed.

*The protein in the flour begin to hydrate and to combine with some water , to form gluten.

*Air bubbles are folded into dough. During the subsequent handling of the dough these bubbles divide or coalesce.

*Enzyme in the yeast start to ferment the sugars present in the flour and later sugar released by diastatic action of the amylases on damaged starch in the flour, breaking them down to alcohol and carbon dioxide.

The dough is then moulded into loaf shape and allowed to rest in the baking pan for 45 to 60 minutes at 38° – 48° C for final proof and is then baked for about 30 minutes with steam injected into the oven to produce a glaze on the crust.

Loaf sized are breads is baked in an oven pre-heated to 204° C. After the first 15 minutes of baking, the temperature is reduced if the crusts become to brown. Baking is continued until the bread is fully baked.

There are four major changes to the dough piece which can be seen as it is baked:

*A large reduction in product density – the dough gets thicker, associated with development of an open porous or flaky structure

*A change of shape associated with shrinkage or spread and increase on thickness

*A reduction in moisture level, to between 1-4%

*A change in surface coloration

Bread baking principle

Most bakery products are made of the same few ingredients – flour, shortening, sugar, eggs, water or milk and leavenings.

The dough is kneaded by hand or machine. After the dough rests for some time (about 2 hours) it is manipulated to push out the gas that has been evolved.

Three process are commence when the ingredients for bread making are mixed.

*The protein in the flour begin to hydrate and to combine with some water , to form gluten.

*Air bubbles are folded into dough. During the subsequent handling of the dough these bubbles divide or coalesce.

*Enzyme in the yeast start to ferment the sugars present in the flour and later sugar released by diastatic action of the amylases on damaged starch in the flour, breaking them down to alcohol and carbon dioxide.

The dough is then moulded into loaf shape and allowed to rest in the baking pan for 45 to 60 minutes at 38° – 48° C for final proof and is then baked for about 30 minutes with steam injected into the oven to produce a glaze on the crust.

Loaf sized are breads is baked in an oven pre-heated to 204° C. After the first 15 minutes of baking, the temperature is reduced if the crusts become to brown. Baking is continued until the bread is fully baked.

There are four major changes to the dough piece which can be seen as it is baked:

*A large reduction in product density – the dough gets thicker, associated with development of an open porous or flaky structure

*A change of shape associated with shrinkage or spread and increase on thickness

*A reduction in moisture level, to between 1-4%

*A change in surface coloration

Bread baking principle

May 11, 2009

The Goals of Modern Food processing

The Goals of Modern Food processing

Formulation

A logical basic sequence of steps to produce an acceptable and quality food product from raw materials.

Easy production procedure

Develop methods that can facilitate the various steps of production.

Time economy

A cohesive plan that combines the science of production and manual labor to reduce the time needed to produce the product.

Consistency

Application of modern science and technology to assure the consistency of each batch of products.

Product and worker safety

The government and the manufacturers work closely to make sure that the product is wholesome for public consumption and the workers work in a safe environment.

Buyer friendliness

Assuming the buyer dislikes the product, the manufacturer must do everything humanly possible to ensure that the product is user friendly (size, cooking instructions, keeping quality, convenience, etc).

Obviously, to achieve all these goals is not a simple matter. The first question is why do we want to process food?

At present, there are many modern reasons why foods are processed, for example, adding value to a food, improving visual appeal and convenience.

However, traditionally the single most important reason we wish to process food is to make last longer without spoiling.

Probably the oldest methods of achieving this goal are the salting of meat and fish, the fermenting of milk and the pickling of vegetable.

The Goals of Modern Food processing

Formulation

A logical basic sequence of steps to produce an acceptable and quality food product from raw materials.

Easy production procedure

Develop methods that can facilitate the various steps of production.

Time economy

A cohesive plan that combines the science of production and manual labor to reduce the time needed to produce the product.

Consistency

Application of modern science and technology to assure the consistency of each batch of products.

Product and worker safety

The government and the manufacturers work closely to make sure that the product is wholesome for public consumption and the workers work in a safe environment.

Buyer friendliness

Assuming the buyer dislikes the product, the manufacturer must do everything humanly possible to ensure that the product is user friendly (size, cooking instructions, keeping quality, convenience, etc).

Obviously, to achieve all these goals is not a simple matter. The first question is why do we want to process food?

At present, there are many modern reasons why foods are processed, for example, adding value to a food, improving visual appeal and convenience.

However, traditionally the single most important reason we wish to process food is to make last longer without spoiling.

Probably the oldest methods of achieving this goal are the salting of meat and fish, the fermenting of milk and the pickling of vegetable.

The Goals of Modern Food processing

August 3, 2006

History of Food Science

History of Food Science

Food is any substance normally eaten or drunk by living organisms. The term food also includes liquid drinks. Food is the main source of energy and of nutrition for animals, and is usually of animal or plant origin. The beginning of food science development is questionable.

The term of food science is referred to interdisciplinary field that evolved first from chemistry, then microbiology, physics, engineering, psychology, genetics, biotechnology and law have become integral parts of this fascinating profession.

The history told us Roman realized, more than Greeks, Egyptians, or any other prior civilizations, that the agriculture was a prime concern for government.

The Romans were able to preserve a variety of foods by holding them in vinegar, honey or pitch. Some foods were dried either by sun or over the fire. These civilizations also produced cheeses or wine.

Food science became a legitimates profession following World War II. Prior to that, the vast majority of food is in the world were prepared locally and so consumers had no option but to visit butchers, bakeries, dairies, green grocers and other purveyors close to their homes and purchase mainly unbranded goods of questionable quality.

Technologies developed in the early and middle 20th century allowed the manufacturer and distribution of canned food, chilled and frozen foods and furnished consumers with electric driven refrigerators and freezers.

History of Food Science

Read also:

Food Science and Society

Food - The Largest of all Industries

Food is any substance normally eaten or drunk by living organisms. The term food also includes liquid drinks. Food is the main source of energy and of nutrition for animals, and is usually of animal or plant origin. The beginning of food science development is questionable.

The term of food science is referred to interdisciplinary field that evolved first from chemistry, then microbiology, physics, engineering, psychology, genetics, biotechnology and law have become integral parts of this fascinating profession.

The history told us Roman realized, more than Greeks, Egyptians, or any other prior civilizations, that the agriculture was a prime concern for government.

The Romans were able to preserve a variety of foods by holding them in vinegar, honey or pitch. Some foods were dried either by sun or over the fire. These civilizations also produced cheeses or wine.

Food science became a legitimates profession following World War II. Prior to that, the vast majority of food is in the world were prepared locally and so consumers had no option but to visit butchers, bakeries, dairies, green grocers and other purveyors close to their homes and purchase mainly unbranded goods of questionable quality.

Technologies developed in the early and middle 20th century allowed the manufacturer and distribution of canned food, chilled and frozen foods and furnished consumers with electric driven refrigerators and freezers.

History of Food Science

Read also:

Food Science and Society

Food - The Largest of all Industries

Subscribe to:

Posts (Atom)

The Most Popular Posts

-

Crude fat is the term used to refer to the crude mixture of fat-soluble material present in a sample. Crude fat also known as the ether ext...

-

Ash or mineral content is the portion of the food or any organic material that remains after it is burned at very high temperatures. The a...

-

Crude fiber is a measure of the quantity of indigestible cellulose, pentosans, lignin, and other components of this type in present foods. ...

-

Density is the weight of a substance per unit of volume, while specific gravity is the ratio between the density of the substance and that o...

-

Gelatinization occurs when starch granules are heated in a liquid. It is responsible for the thickening of food systems. The process is an i...